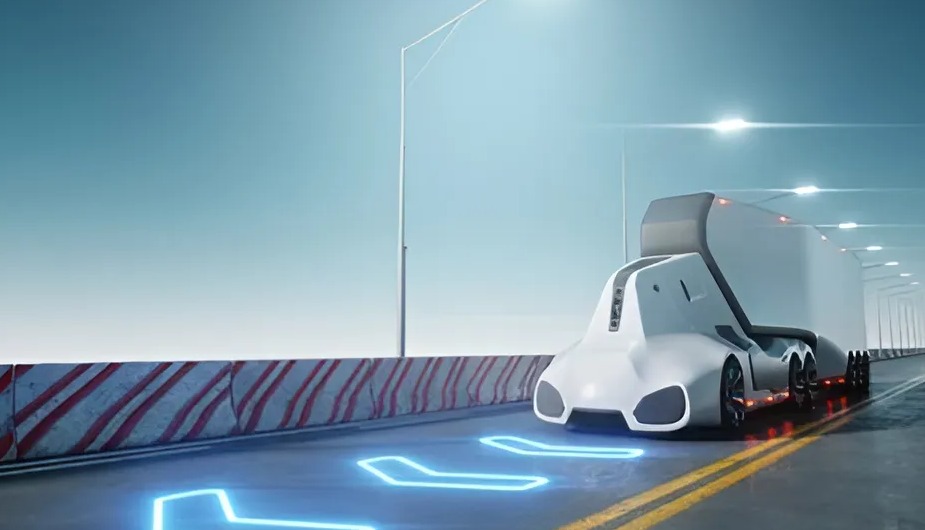

Autonomous vehicles are changing how warehouses operate by using advanced technologies like AI, machine learning, and IoT. These vehicles have sensors and navigation systems that allow them to move around warehouses and complete tasks without much human involvement. In this article, we will look at how these vehicles transform warehouse operations and discuss their benefits, challenges, and future impact.

How Autonomous Vehicles Improve Warehouse Processes

Autonomous vehicles in warehouses work by using automation to make different parts of the warehouse process better. They can:

- Make picking and packing faster and more efficient

- Help manage inventory better

- Improve warehouse security with surveillance features

Understanding how autonomous vehicles can help with warehouse management will give you useful information on how to use this technology for smooth operations.

Why Embracing Autonomous Vehicles in Warehouses Matters

By embracing autonomous vehicle technology in warehouses, businesses can achieve:

- Enhanced operational efficiency

- Improved worker safety

- Higher order accuracy

- Cost savings through labor optimization

However, there are also challenges to overcome, such as:

- High initial investment costs

- Safety regulations that need to be followed

Even with these challenges, integrating autonomous vehicles has a lot of potential to change the warehousing industry and how businesses plan their supply chains.

Stay tuned as we explore each aspect of integrating autonomous vehicles in warehouses to understand their advantages, challenges, and potential impact on the future of warehouse operations.

1. The Role of Autonomous Vehicles in Optimizing Warehouse Processes

Autonomous vehicles are revolutionizing warehouse operations by transforming different aspects of warehouse processes through automation and advanced technologies like AI, machine learning, and IoT. These vehicles play a vital role in streamlining warehouse operations, enhancing efficiency, and improving overall productivity.

1.1 Picking and Packing

Autonomous vehicles are significantly improving the picking and packing processes in warehouses. With their ability to navigate efficiently and carry out tasks accurately, these vehicles are streamlining operations. For example, autonomous robots equipped with computer vision systems can easily identify products on shelves and pick them up without any human intervention.

Real-world examples highlight the benefits of using autonomous vehicles for picking and packing operations. For instance, companies like Amazon have implemented autonomous robots in their warehouses, resulting in significant improvements in productivity and order accuracy. These robots can execute picking tasks at a much faster pace than human workers, reducing processing times and increasing efficiency.

1.2 Inventory Management

Autonomous vehicles also play a crucial role in inventory management within warehouses. By enabling real-time data capture and analysis, these vehicles ensure accurate inventory tracking, reduce stockouts, and optimize storage space utilization.

Improved inventory visibility is one of the key benefits that warehouses can derive from the integration of autonomous vehicle technology. With real-time data capture, warehouses can have better control over their inventory levels, leading to timely replenishment and reduced out-of-stock situations. This not only improves operational efficiency but also enhances customer satisfaction by minimizing order delays.

1.3 Warehouse Security

The potential for autonomous vehicles to enhance security measures in warehouses is another crucial aspect to consider. These vehicles can be equipped with surveillance capabilities and access control systems to monitor warehouse premises effectively.

However, it’s important to mention potential challenges or concerns related to privacy and cybersecurity that may arise with the deployment of autonomous vehicle security solutions. As these vehicles collect data and operate within the warehouse environment, ensuring data privacy and protecting against cyber threats becomes a critical consideration for warehouse managers.

2. Advantages of Integrating Autonomous Vehicles for Efficient Warehouse Management

The integration of autonomous vehicles in warehouse management offers a wide array of benefits that contribute to improved operational efficiency and productivity. Some of the key advantages include:

Improving Operational Efficiency and Boosting Productivity: Autonomous vehicles streamline warehouse processes, such as picking, packing, and inventory management, leading to faster task completion and overall operational optimization.

Enhanced Safety and Ergonomics for Workers: By handling repetitive or physically demanding tasks, autonomous vehicles reduce the risk of workplace injuries and alleviate ergonomic strain on human workers.

Achieving Cost Savings through Labor Optimization: The use of autonomous vehicles in warehouse operations can lead to significant cost savings by optimizing labor resources and reducing reliance on manual labor for certain tasks.

3. Overcoming Challenges in the Integration of Autonomous Vehicles

The integration of autonomous vehicles in warehouse operations presents several challenges that warehouses need to address:

1. High Initial Investment Costs

The upfront investment for acquiring and implementing autonomous vehicle technology can be substantial, posing a financial barrier for many warehouses. However, this challenge can be mitigated by considering the long-term cost savings and operational efficiencies offered by autonomous vehicles. Conducting a thorough Cost-Benefit Evaluation and exploring financing options or partnerships with technology providers can help alleviate the financial burden.

2. Limited Adaptability to Existing Infrastructure

Warehouses with traditional layouts and infrastructure may find it challenging to seamlessly integrate autonomous vehicles into their operations. Retrofitting existing facilities to accommodate autonomous vehicle navigation systems and infrastructure may require significant modifications. To overcome this challenge, warehouses can gradually phase in autonomous vehicles, starting with specific processes or areas and gradually expanding as infrastructure upgrades are made. Resources such as those provided by the Institute for Vehicle Systems & Control could prove helpful in this regard.

3. Regulatory and Legal Considerations for Safety Compliance

The deployment of autonomous vehicles in warehouses raises important Compliance with Regulations and Safety Standards considerations. Warehouses must adhere to industry-specific regulations, safety standards, and operational protocols to ensure the safe integration of autonomous vehicles. Collaborating with regulatory authorities, seeking expert legal counsel, and investing in comprehensive training programs for employees can help warehouses navigate the complex landscape of regulatory compliance.

By addressing these challenges proactively, warehouses can pave the way for successful integration of autonomous vehicles, unlocking the transformative potential of advanced automation technologies in warehouse management.

4. The Future Landscape of Warehouses with Autonomous Vehicles

The use of autonomous vehicles in warehouses is more than just a passing trend. It offers a glimpse into what the Evolution of Warehouse Management could look like. As technology progresses, autonomous vehicles will play an even bigger role in shaping how warehouses operate. In this section, we’ll explore the possible long-term effects of autonomous vehicles on the industry and how they could influence future business models and supply chain strategies.

Towards Fully Automated Warehouses?

One potential direction for warehouses in the future is complete automation. With Innovations in Robotics and Artificial Intelligence (AI), it’s possible to imagine warehouses that are entirely run by machines. Autonomous vehicles would take care of everything from moving materials to fulfilling orders. This level of automation could bring significant benefits in terms of efficiency, accuracy, and productivity.

Picture a warehouse where autonomous vehicles seamlessly collaborate to handle tasks like picking items for orders, packing them, managing inventory, and even transporting goods within the facility. This high degree of automation would greatly reduce mistakes made by humans, increase the rate at which orders are processed, and enable warehouses to operate non-stop without relying on human workers.

Embracing a Hybrid Approach: Humans and Machines Working Together

While fully automated warehouses may sound appealing to some, there are still practical challenges that need to be overcome before they can become a reality. One approach that’s gaining traction is a collaborative model blending human and machine labor.

In this scenario, humans would focus on jobs that require thinking critically, making decisions, and solving problems—tasks that machines currently struggle with. Meanwhile, autonomous vehicles would take care of repetitive and physically demanding work. By combining the strengths of both humans and machines, warehouses can achieve optimal efficiency while ensuring quality control.

Collaborative Intelligence: Humans and AI Joining Forces

To fully realize the potential of this hybrid model, warehouses need to embrace the concept of collaborative intelligence. This entails humans and AI working together synergistically to accomplish tasks more efficiently than either could do alone.

In this context, humans would leverage their critical thinking abilities to supervise and manage operations, while AI-powered systems would provide real-time data analysis, predictive insights, and automated decision-making support. The combination of human intuition and machine precision would enable warehouses to optimize their processes, enhance customer service, and drive innovation.

Conclusion

Integrating autonomous vehicles into warehouse operations has the potential to greatly improve warehouse management in the future. The combination of autonomous vehicle technology, AI, machine learning, and IoT capabilities is transforming how warehouses operate.

By using autonomous vehicles, warehouses can:

- Optimize picking and packing operations

- Improve inventory management with real-time data analysis

- Enhance security through surveillance capabilities

The benefits of integrating autonomous vehicles include:

- Improved operational efficiency and productivity

- Enhanced worker safety and ergonomics

- Higher order accuracy

- Cost savings through optimized labor usage

However, there are also challenges that come with integrating autonomous vehicles:

- High initial investment costs

- Limited adaptability to existing infrastructure

- Regulatory requirements for safety compliance

Looking ahead, the future of warehousing with autonomous vehicles could involve fully automated warehouses or a combination of human-machine collaboration. Warehouse managers should stay updated on the latest developments in autonomous vehicle technology and consider pilot projects or partnerships to assess its feasibility in their own warehouses.

By embracing autonomous vehicle technology, warehouses can lead the way towards more efficient operations, increased productivity, and greater customer satisfaction.