Discover how to manage temperature-sensitive goods in logistics, ensuring product quality, compliance, and customer satisfaction in your supply chain.

Introduction:

In the logistics industry, managing temperature-sensitive goods in logistics is vital for maintaining product quality and safety From pharmaceuticals to perishable food items, temperature-sensitive goods in logistics require strict monitoring and control throughout the supply chain.This blog discusses best practices for managing temperature-sensitive goods in logistics and why implementing effective strategies is crucial for success.is blog discusses best practices for managing temperature-sensitive goods in logistics and why implementing effective strategies is crucial for success.

Understanding Temperature-Sensitive Goods

Temperature-sensitive goods are products that require specific temperatures to maintain their quality and effectiveness. These goods can include:

- Pharmaceuticals: Many medications must be stored and transported at controlled temperatures to preserve their efficacy.

- Food Products: Perishable items like fruits, vegetables, dairy, and meats require refrigeration to prevent spoilage and ensure consumer safety.

- Biologics and Vaccines: These products often have strict temperature requirements, making proper handling essential to prevent degradation.

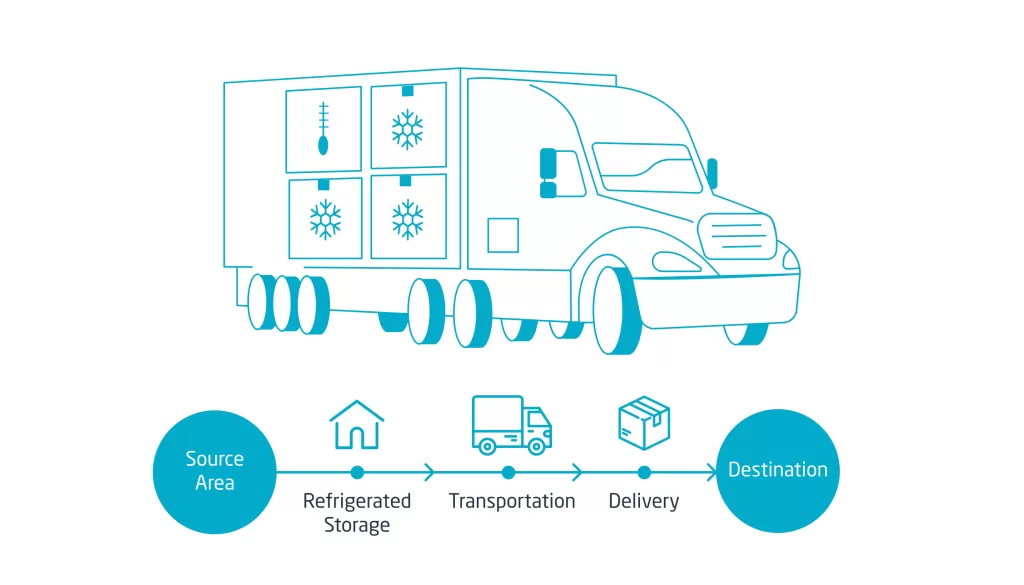

In logistics, the challenge lies in ensuring that these items remain within their required temperature ranges from the moment they leave the manufacturer until they reach the end consumer.

The Importance of Temperature Control in Logistics

- Quality Assurance

Maintaining the quality of temperature-sensitive goods in logistics is crucial. A slight deviation from the recommended temperature can lead to product spoilage or loss of potency, particularly in pharmaceuticals. Proper temperature management of temperature-sensitive goods in logistics safeguards product integrity, ultimately ensuring customer satisfaction. - Regulatory Compliance

For many temperature-sensitive goods, especially pharmaceuticals, compliance with regulatory standards is mandatory. Organizations must adhere to guidelines set by regulatory bodies, such as the FDA or EMA. Failing to meet these standards can result in penalties, recalls, or damage to brand reputation. - Cost Efficiency

Managing temperature-sensitive goods effectively can lead to cost savings. By minimizing spoilage and waste, companies can maximize their profit margins. Additionally, efficient handling reduces the need for emergency interventions due to product loss.

Best Practices for Managing Temperature-Sensitive Goods

1. Utilize Technology for Monitoring and Control

Advancements in technology have made it easier to monitor temperature-sensitive goods. Companies can use:

- Real-Time Temperature Monitoring Systems: These systems track the temperature of goods throughout the supply chain, providing alerts if temperatures deviate from the required range.

- Data Loggers: These devices can record temperature data at set intervals, offering valuable insights into storage conditions and enabling companies to analyze trends over time.

2. Train Employees

Proper training of staff handling temperature-sensitive goods is essential. Employees should understand the importance of temperature control, how to use monitoring equipment, and procedures for responding to temperature deviations. Training should also cover proper loading and unloading techniques to minimize temperature fluctuations during transportation.

3. Implement Standard Operating Procedures (SOPs)

Developing and enforcing SOPs for handling temperature-sensitive goods is crucial. These procedures should include:

- Loading and Unloading Protocols: Clear instructions on how to load temperature-sensitive goods to maintain their integrity.

- Emergency Procedures: Guidelines for handling temperature deviations, including whom to notify and how to mitigate potential damage.

4. Choose the Right Packaging

Effective packaging plays a significant role in maintaining the temperature of sensitive goods. Companies should select packaging materials that provide insulation and protection from temperature fluctuations. Options like thermal blankets, gel packs, and insulated containers can help preserve the required temperature during transportation.

5. Optimize Transportation Methods

Selecting the appropriate transportation methods for temperature-sensitive goods is critical. Considerations should include:

- Transportation Mode: Air freight may be suitable for time-sensitive deliveries, while trucking may be more cost-effective for larger shipments.

- Carrier Experience: Choose carriers with experience in handling temperature-sensitive goods and the necessary equipment for maintaining temperature control.

6. Regular Audits and Inspections

Conducting regular audits and inspections of temperature-sensitive goods can help identify potential issues before they escalate. Companies should assess:

- Storage Facilities: Ensure that storage areas are equipped with proper refrigeration and monitoring systems.

- Transportation Vehicles: Verify that vehicles are well-maintained and capable of maintaining the required temperature during transit.

The Future of Managing Temperature-Sensitive Goods

As the demand for temperature-sensitive goods continues to rise, logistics companies must invest in innovative solutions to manage these products effectively. The integration of advanced technologies, such as IoT and AI, will enable more accurate monitoring and predictive analysis, allowing for proactive temperature management.

Additionally, as consumers become more health conscious and environmentally aware, the demand for quality and sustainability in logistics will grow. Companies must adapt to these trends by implementing sustainable practices in managing temperature-sensitive goods, such as using eco-friendly packaging and optimizing transportation routes.

Conclusion: Ensuring Quality and Safety in Logistics

In conclusion, managing temperature-sensitive goods in logistics is a critical aspect of ensuring product quality, compliance, and customer satisfaction. By implementing effective monitoring systems, training staff, and establishing standard operating procedures, companies can enhance their ability to handle these goods safely and efficiently. As technology continues to evolve, logistics firms that prioritize temperature-sensitive goods in logistics will be better positioned to meet the demands of an increasingly complex supply chain.